Commercial Refrigeration: The Cool Runnings

Commercial Refrigeration: The Cool Runnings

In the bustling kitchens of a high-end restaurant, the hum of the walk-in freezer mingles with the clatter of pots and pans. Meanwhile, in the sterile environs of a pharmaceutical facility, the precise cooling of compounds holds the key to breakthroughs in modern medicine. Wherever you stand on the spectrum, from gourmet gastronomy to life-saving drug development, you’re bound by a common thread—reliance on commercial refrigeration and HVAC systems.

For HVAC technicians, commercial kitchen owners, and managers overseeing facilities both vast and intricate, a deep understanding of AC and commercial refrigeration is not just a convenience—it’s a mandate. This post unravels the labyrinthine mechanics of cooling technology, providing a helpful guide for professionals in these fields as well as anyone interested in the unseen marvels that keep our modern world, quite literally, cool.

Chapter 1: The Chilled Prologue – A Historical Overview

Before we plunge into the meat and potatoes—chances are, temperature controlled—the historical context of AC and refrigeration merits a glance backward. While we often associate refrigeration with modern convenience, the idea of controlling climate dates back centuries. In 1748, William Cullen, a Scottish physician, demonstrated artificial refrigeration for the very first time. Fast forward to 1851, and Australian James Harrison would pioneer an ice-making machine that would mark the advent of modern refrigeration.

AC’s lineage is similarly storied, with the first modern air conditioning system designed in 1902 by an engineer named Willis Haviland Carrier, who sought to solve a humidity problem affecting a publishing company’s paper. These nascent breakthroughs paved the way for the technological marvels we take for granted today.

Chapter 2: The Science Behind the Breeze

Understanding the basics of thermodynamics is essential for anyone in the business of cooling. At its core, refrigeration operates on the simple principle that heat naturally moves from hot areas to cold areas. Refrigeration systems manipulate this process to cool air or liquid at specific locations. Vapor-compression and absorption refrigeration are two common methods employed to achieve this, harnessing the properties of various refrigerants to transfer heat efficiently and safely.

In an air conditioning context, the process involves not only cooling but also dehumidifying the air. This dual function is critical for creating the ideal climate in diverse settings. Modern advancements, such as variable refrigerant flow (VRF) systems, have taken energy efficiency and user control to new heights, solidifying AC as a pillar of 21st-century comfort and utility.

Chapter 3: Commercial Refrigeration – From Farm to Fork

The scope of commercial refrigeration is as wide as the applications are varied. From walk-in coolers at the local grocer to high-tech installations in industrial food and beverage processing, the technology involved is complex and critical to maintaining product integrity and safety.

For instance, retailers often tout the superiority of their ‘fresh’ offerings, and for good reason. A robust ‘cold chain’—an uninterrupted series of refrigerated production, storage, and distribution activities—ensures that perishable goods maintain their freshness from the moment they’re harvested to the instant they’re purchased.

Chapter 4: Refrigerants Then and Now

The story of refrigerants is one of evolution driven by environmental concerns. The notorious CFCs and HCFCs, once mainstays of cooling systems, were found to be major contributors to ozone layer depletion, ushering in a global phaseout through agreements like the Montreal Protocol. Hydrofluorocarbons (HFCs), initially praised for their benign impact on the ozone, were later recognized for their significant greenhouse gas potential, sparking the move toward low-GWP (global warming potential) alternatives in recent years.

Refrigerant selection is thus not just a technical consideration but a moral one, dovetailing with the global imperative to combat climate change.

Chapter 5: The Internet of Refrigerated Things – Smart Technology in AC and Refrigeration

The digital revolution isn’t just changing the way we live and work—it’s also reshaping the realm of AC and refrigeration. Smart technology, including the Internet of Things (IoT), is enabling unprecedented monitoring, control, and automation of cooling systems. This connectivity isn’t merely a convenience; it’s a game-changer for predictive maintenance, energy optimization, and real-time adjustments based on usage and environmental factors.

Chapter 6: The Human Element – Maintenance, Troubleshooting, and Best Practices

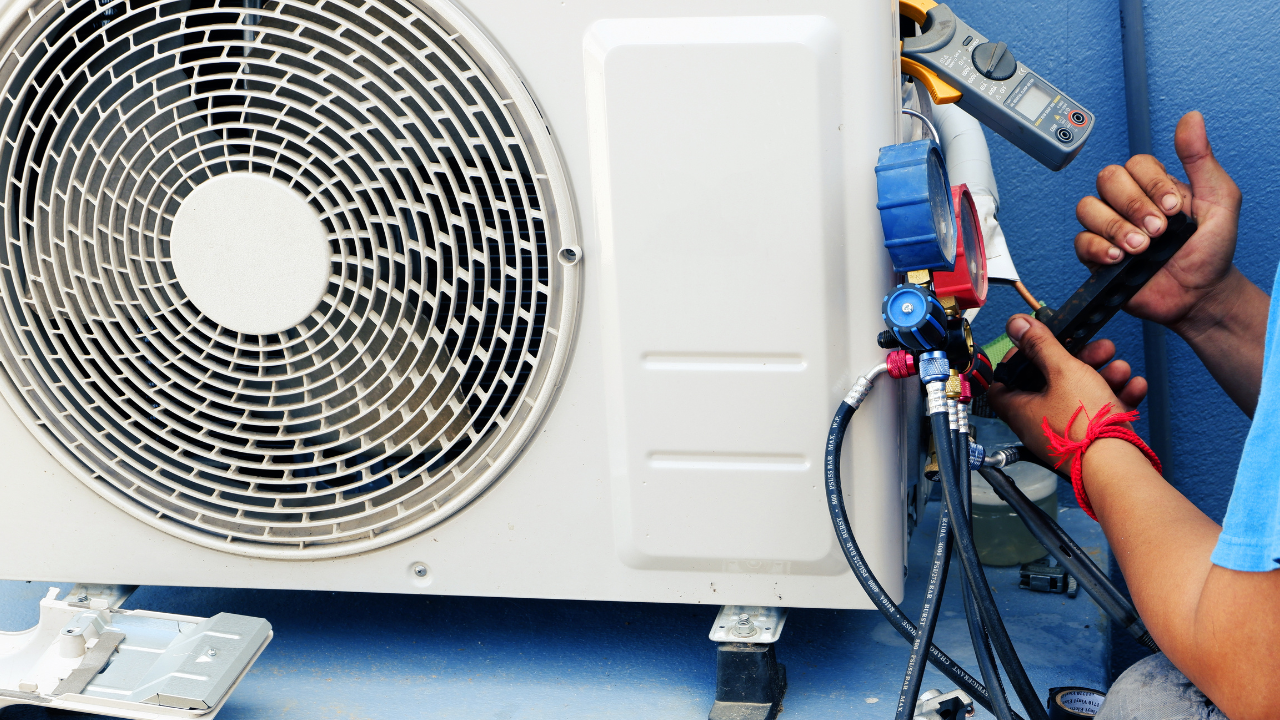

A cooling system is only as good as the care it receives, and that’s where the expertise of technicians comes into play. Regular maintenance is essential for preventing downtime and preserving the lifespan of AC and refrigeration units. Best practices for commercial air conditioning (A/C) and refrigeration unit maintenance include:

- Establish a Maintenance Schedule: Set up a regular maintenance schedule for your A/C and refrigeration units, ideally quarterly or bi-annually, to ensure consistent upkeep.

- Perform Regular Inspections: Conduct routine visual inspections of your units to check for any signs of wear, damage, or leaks.

- Clean or Replace Air Filters: Clean or replace air filters regularly to maintain good indoor air quality and prevent strain on the system.

- Keep Condenser Coils Clean: Regularly clean condenser coils to remove dirt, debris, and buildup, which can hinder heat transfer and decrease efficiency.

- Refrigerant Levels: Keep an eye on refrigerant levels and perform leak tests to ensure optimal performance and prevent potential environmental damage.

- Check for Airflow Restrictions: Ensure that vents and ductwork are free from obstructions to maintain proper airflow and prevent uneven cooling or heating.

- Inspect Electrical Components: Regularly inspect electrical connections, controls, and wiring for signs of wear, corrosion, or damage to prevent system malfunctions or breakdowns.

- Lubricate Moving Parts: Lubricate moving parts such as motors, fans, and bearings to reduce friction and extend the lifespan of components.

- Test System Controls: Test and calibrate system controls, including safety controls and sequences, to ensure proper operation and safety compliance.

- System Performance Monitoring: Use analytical monitoring tools to track energy consumption, temperature fluctuations, and other metrics to identify potential issues early and optimize system efficiency.

In a field increasingly dominated by automation, the human touch remains irreplaceable, however, emphasizing the value of experience and intuition when confronting complex cooling conundrums. When it comes to complex problem-solving skills and sensory perception, human technicians can use their senses to detect subtle cues that automated systems may overlook. They can assess unique situations, adjust strategies on the fly, and apply creative solutions that may not be programmed into automated systems.

Chapter 7: Going Green – Sustainability and Commercial Cooling

Sustainability isn’t just a buzzword; it’s a business imperative and an ethical responsibility in the modern world. The commercial cooling sector is no exception, with stakeholders working to decrease energy consumption, minimize refrigerant leaks, and employ renewable energy sources wherever feasible.

Sustainable initiatives transform the AC and refrigeration industry, from the engineering of more efficient systems to the adoption of circular economy practices that reduce waste and resource consumption. Enhanced regulatory measures and certifications on the development and deployment of sustainable cooling solutions help us pave the way forward to a greener planet.

Chapter 8: The Future on Ice – Emerging Trends and Where Cooling Is Headed

This final chapter is a speculative gaze into the crystal ball, examining emerging trends that may redefine cooling technology in the years to come. Innovations such as magnetic refrigeration, which eschews traditional compressor technology for a more efficient and environmentally friendly approach, and the use of phase-change materials for energy storage, offer tantalizing glimpses of the future’s chilly potential. Below are our top 5 A/C trends to follow:

- Thermoelectric Cooling: Thermoelectric cooling utilizes the Peltier effect to create a temperature difference across a semiconductor device, allowing heat to be transferred from one side to the other. This technology has the potential to revolutionize cooling systems by offering more energy-efficient and environmentally friendly alternatives to traditional refrigeration methods.

- Magnetic Refrigeration: Magnetic refrigeration relies on the magnetocaloric effect, where a magnetic field is used to manipulate the temperature of a material, causing it to absorb or release heat. This technology has the potential to be more energy-efficient, quieter, and environmentally friendly compared to conventional vapor compression refrigeration systems.

- Solid-State Cooling: Solid-state cooling systems use semiconductor materials to transfer heat, eliminating the need for traditional refrigerants such as CFCs or HCFCs. These systems are more compact, have no moving parts, and offer greater reliability, making them ideal for various cooling applications, including electronics cooling and medical refrigeration.

- Desiccant Cooling: Desiccant cooling systems use desiccant materials to remove moisture from the air, reducing its humidity and lowering the temperature through evaporative cooling. These systems can be more energy-efficient in certain climates and applications, particularly in dry or arid regions where traditional air conditioning may be less effective.

- Passive Cooling: Passive cooling techniques leverage natural processes such as convection, radiation, and evaporative cooling to regulate temperature without the need for mechanical systems. Examples include building design strategies such as shading, insulation, natural ventilation, and thermal mass. Passive cooling technologies can complement active cooling systems, reducing energy consumption and enhancing overall efficiency.

These emerging technologies have the potential to revolutionize cooling systems by offering more energy-efficient, environmentally friendly, and innovative alternatives to traditional refrigeration methods. As research and development in these areas continue to advance, we can expect to see further advancements and widespread adoption of these technologies in the future.

Whether it’s ensuring the safety of our food supply, the efficacy of manufacturing processes, the comfort of office buildings, or the health of research laboratories, the significance of AC and refrigeration in all our lives is unassailable. By grounding themselves in the principles, practices, and innovations that define this domain, professionals in the space will not only excel in their careers but also contribute to a world that is both well-refrigerated and well-served. In a world that’s reeling from climate challenges, the role of the cooling industry takes on an even greater significance.

Overall, upgrading your AC unit can provide numerous benefits, including improved energy efficiency, enhanced comfort, increased reliability, better indoor air quality, environmental sustainability, and access to advanced technologies and features. It’s a worthwhile investment that can pay off in terms of cost savings, comfort, and peace of mind in the long run.

Level One HVAC has been serving the metro Detroit area for two decades, providing specialized air and refrigeration services to commercial, industrial, and institutional facilities. For more information about how our services please check us out here. Or contact us and one of our customer service representatives will get back with you shortly!

New Hudson, MI #248.486.6500

West Branch, MI #989.999.4822